Keep machines running without interruption

With the 10DER system, operators can load parts once and let the tending cell keep production going through breaks, shift changes, or weekends. The result is maximized spindle uptime and more predictable delivery schedules.

_JPG.jpg)

Adds 128 unmanned hours

per week of production with

lights-out operation

143% Increase

in spindle utilization with automation

6-18 months ROI

when implementing 2-shift operations

90% Reduction

in part-to-part variation

Boost productivity with the ultimate automated machine tending solution tailored to your unique production needs. Designed to seamlessly integrate with CNC lathes and milling machines, flexible 10DER® Machine Tending Systems enable around-the-clock production while maintaining exceptional precision. Perfectly suited for high-mix, low-volume manufacturing, 10DER systems free up your skilled operators to focus on higher-value tasks, enhancing overall workflow efficiency.

-

Rapid Setup: Simple touch off points, create part programs with the intuitive interface, and start production. No robotics experience is required.

-

Easy Redeployment: Built-in forklift pockets allow for effortless movement between CNC machines.

-

Flexible Programming: Pre-programmed part positions for streamlined load/unload sequences can be easily edited to accommodate a wide range of part sizes.

Adjustable Grippers & End-of-Arm Tooling

Adapt quickly between jobs and improve precision handling without frequent tool swaps. 10DER TS-X comes with a standard pneumatic gripper and the ability to handle a wide range of part sizes with customizable EOAT options.

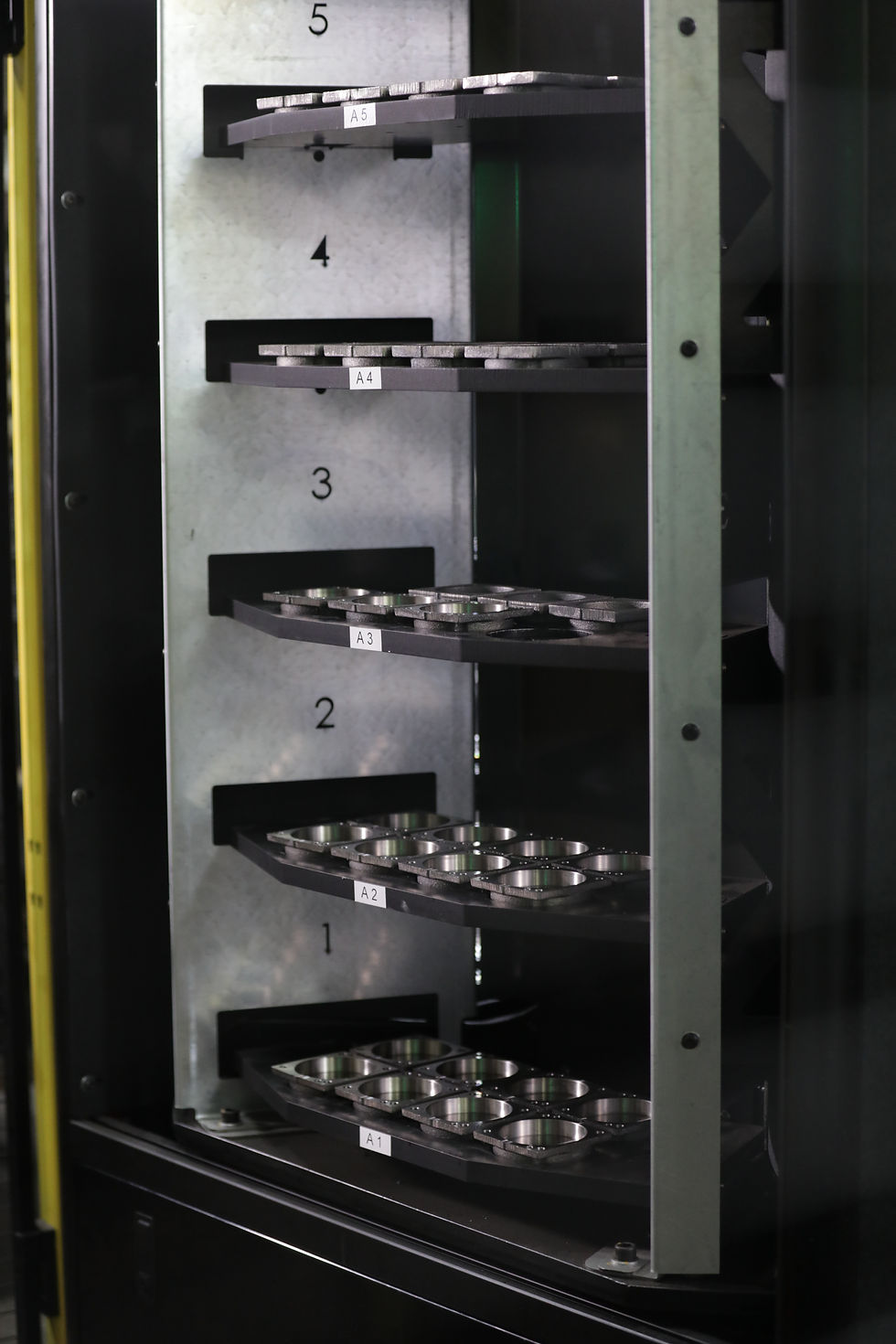

Customizable Pallet Shelves

Three-sided access and modular shelving streamline part handling, resulting in faster workflow, more storage, and adaptable part compatibility.

-

Load/unload from three sides

-

20 shelves, 600 kg total load

-

Inserts and peg fixtures are available for unique parts

-

Capability to batch different part numbers per shelf with able/disable options

-

Ability to load the 10DER with pallets for extended milling cycles, particularly on 5- or 6-axis machines.

Scalability

In addition to the standard 10DER® TS-X unit equipped with sensors, pneumatic valve stacks, and electrical sensor connections via the internet, you can add optional accessories such as:

-

Vision system

-

Inspection – CMM

-

Re-Grip station mounts

-

Drilling/Deburr/Part Press kits available

-

Custom EOAT tool designs & grippers

User-Friendly Touchscreen Interface

An intuitive icon-based touchscreen features centralized control and real-time system notifications. Minimal training is needed for operation, and you can create part numbers and programs directly on the HMI screen.